Filtermist’s experienced team works with many high-profile pharmaceutical companies to ensure the air in their production facilities is clean and safe to breathe, and potentially expensive waste is minimised. In the current climate with production of pharmaceutical products in overdrive, maintaining safe working environments is more important than ever. From centralised dust control systems, to individual filtration units which include a range manufactured under the company’s Dustcheck brand, and replacement filter cartridges - Filtermist offers a comprehensive clean air solution for pharmaceutical manufacturers of all sizes.

Dustcheck Product Manager Andy Darby comments, “We do offer a standard range, but our products can also be designed to accommodate specific customer requirements. This can include units that feature ‘Safe Change’ or ‘Clean Change’ filter element removal to meet workplace exposure limits by protecting the operator from particularly toxic or unpleasant dust.

“We work with many of the UK’s leading pharmaceutical manufacturers, providing filtration for a variety of stages in the production process.”

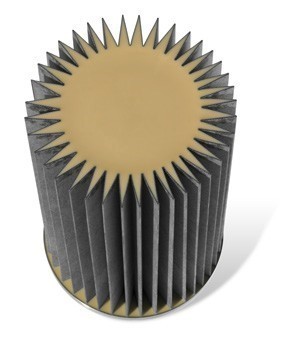

Conical filter technology

Manufactured with stainless steel end caps and star-pleated filter material, the Filtration Group GmbH unique conical filters, used for our Dustcheck units, are perfectly matched with the multi-jet cleaning system which features in most Dustcheck filtration units. This system ensures that dust is effectively removed during cleaning with no loss of suction, as well as significantly reducing noise.

Dustcheck’s Compact 120 Series (SFKJC) benefits from circular construction and is suitable for high pressures - both positive and negative. It is also well suited for hygienic applications with no internal ledges for product to gather on, making it an extremely popular solution for pharmaceutical applications.

This range of filters is compliant with European legislation EC 1935/2004 for food-contact materials and EU No. 10/2011 on the marketing of materials, as well as US FDA legislation.

Manufactured from Silicon, the seals supplied with the cartridges avoid ledges and areas where dust can gather - they have been independently laboratory tested and approved to meet the requirements of EU No. 10/2011 and FDA for use in the pharmaceutical and food industry. The seals can be removed and washed, making them well suited to meet the demands of hardworking production applications.

Alongside the polyester based filter materials, specialised materials that provide increased chemical resistance are also available - these also conform to FDA and EU No. 10/2011.

Filter Material

Dustcheck cartridges are manufactured by Filtration Group GmbH which is currently the only supplier of electrically conductive filter material in white - something that was requested from industry users, particularly in the food and pharmaceutical industries.

The use of electrically conductive filter material is important where an electrostatic discharge of the built up charge can pose problems, for example in potentially explosive atmospheres (ATEX).

Designated TI 2011, the filter material has been independently tested to ensure it meets the requirements of DIN EN 54345 part 5 – Testing of textiles; Electrostatic behaviour; Determination of electrical resistance of strips of textile fabrics.

Using a PTFE membrane, the cartridges have a smooth lint free surface and good chemical resistance along with excellent cleaning and filtration efficiency. Tests against the requirements of DIN EN 60335-2-69 have awarded a classification of “M” where the exhaust air must not contain more than 0.1% of the material collected.

This filter material also meets the requirements of FDA and EU No. 10/2011.

For more information please visit: www.dustcheck.com or watch this short film to find out more about the benefits of Dustcheck’s conical filter technology.