The Dustcheck Team were playing a game of ‘spot the Dustcheck unit’ when last week’s 'Inside the Factory', filmed at Soreen, aired on BBC2.

It piqued the interest of the Dustcheck team as several of the factory’s dust control and air filtration systems were designed and installed by the team!

It’s not the first time Dustcheck products have featured on the show and in Wednesday’s episode, hosted by Gregg Wallace and Cherry Healey, they visited the factory in the North West to take a look at how its famous malt loaf is manufactured.

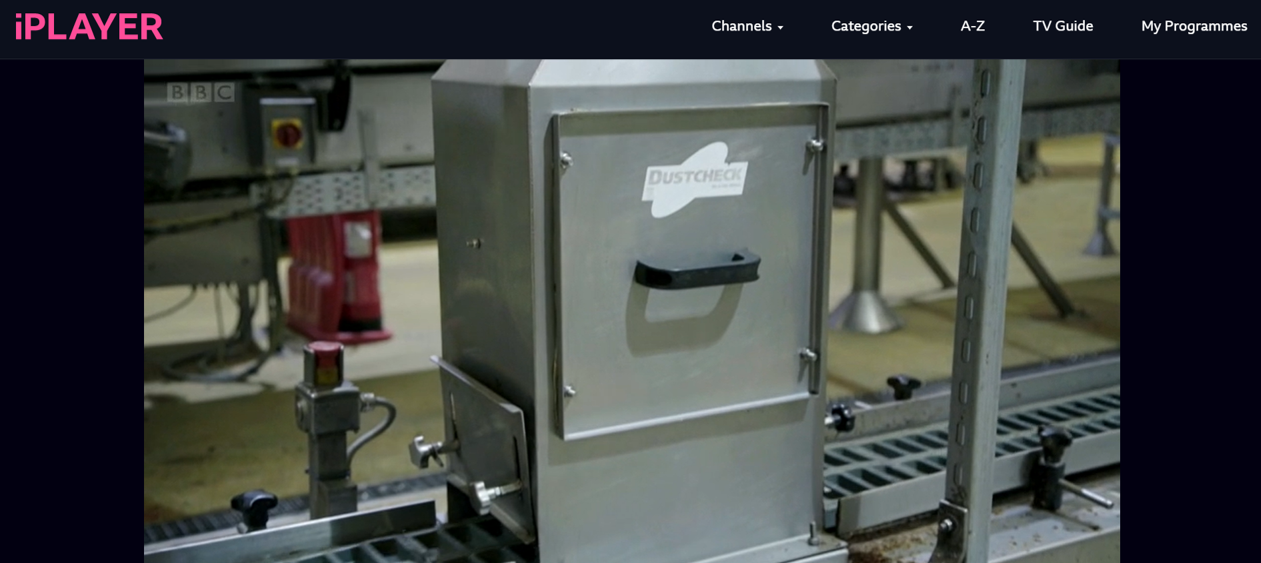

As part of Soreen’s production line the loaf trays pass through a ‘crumb-blaster’ (pictured below) which was an unusual and bespoke piece of equipment designed by Dustcheck. The unit houses an air-knife which uses high-pressure jets of air to blast off baked-on malt loaf from the tins. The unit is connected to a Local Exhaust Ventilation (LEV) system and draws the crumb waste up and into a Dustcheck Maxi-Bag (circular reverse jet cleaning tubular bag dust collector), and the waste dust collected in an integral hopper bin.

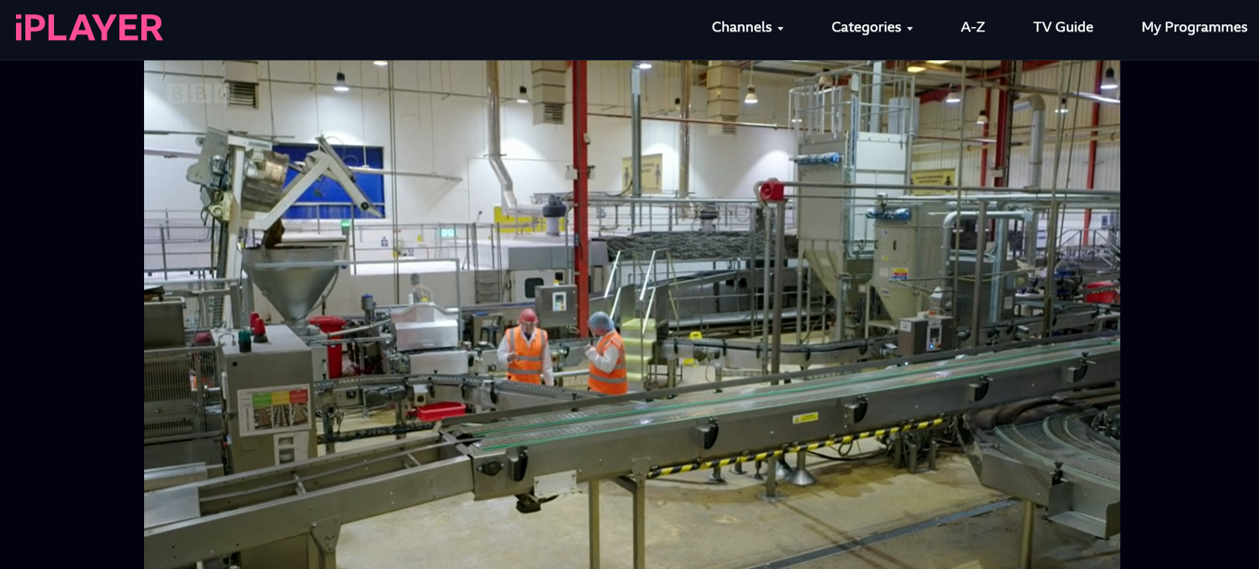

As well as the impressive ‘crumb-blaster’ the system also includes a Centralised Vacuum Cleaning System (pictured below) which incorporates another Maxi Bag dust collector, ducting and hose outlets throughout the factory to help with housekeeping.

“This was one of the most challenging jobs I’ve worked on at Dustcheck. The production line is hot, meaning the oil in the mixture was still in liquid form in the air we’re extracting. We specified the Maxi-Bag Series as the filter media we needed to use had to be able to handle this. We designed a bag filtration unit with tubular socks that were manufactured with a polyester needlefelt media that also had an oleophobic coating to handle the oily product being filtered,” said Troy Birnie, Applications Engineer.

Dustcheck products are manufactured by Filtermist International Limited based in Telford. Centralised Vacuum Cleaning Systems are now part of the Kerstar range of products, another brand manufactured by Filtermist. The systems collect all waste in one central location for fast and efficient disposal. Centralised Vacuum Cleaning Systems can be used for general cleaning systems where a range of tool attachments are available to suit the customers’ needs – they are also ideal for heavy-duty material transfer. For more information visit: www.kerstar.com/centralised-vacuum-systems

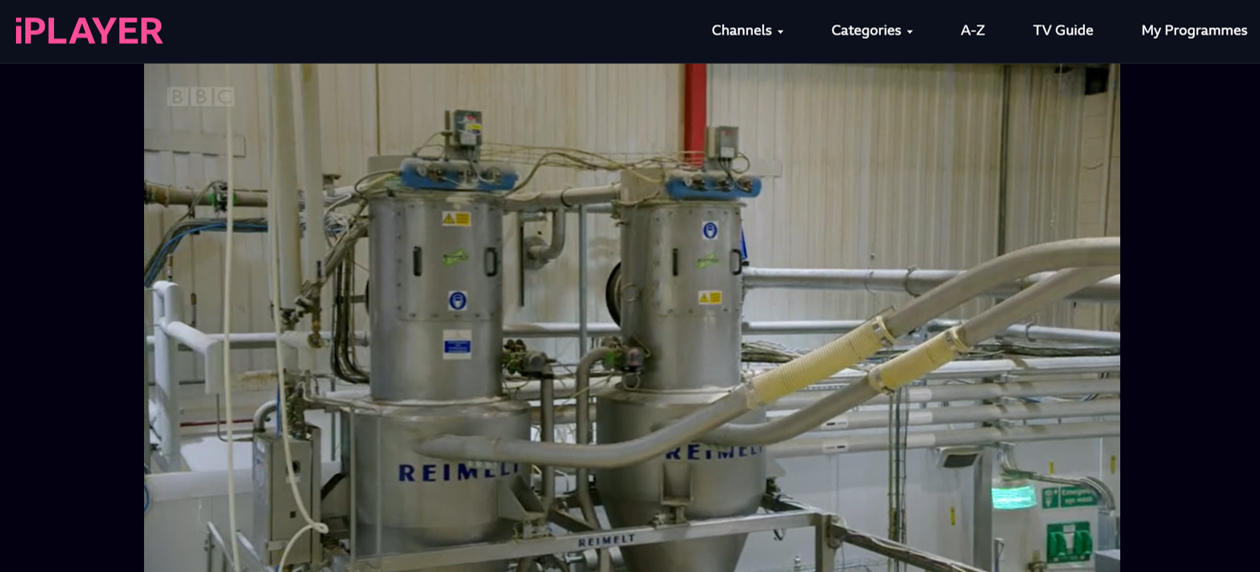

The product spotting didn’t stop there though, as elsewhere in the episode we saw Greg Wallace in the Mixing Station area of the factory where more of Dustcheck’s products made it on screen. Here we saw two stainless steel ProGuard Series venting filters (pictured below) attached to the top of two huge mixing units.

These cartridge filter units are capable of handling high dust loads and the ledge-free, circular design provides hygienic capture and filtration of particulates which lends the range particularly well to food industry applications.

For more information on the Dustcheck products featured on the show or for any other products in our range visit: www.dustcheck.com